Human beings may have a history of being good at many different things, but at the same time, there remains little that we do better than growing on a consistent basis. This tendency to improve, …

Human beings may have a history of being good at many different things, but at the same time, there remains little that we do better than growing on a consistent basis. This tendency to improve, no matter the situation, has brought the world some huge milestones, with technology emerging as quite a major member of the group. The reason why we hold technology in such a high regard is, by and large, predicated upon its skill-set, which guided us towards a reality that nobody could have ever imagined otherwise. Nevertheless, if we look beyond the surface for one hot second, it will become abundantly clear how the whole runner was also very much inspired from the way we applied those skills across a real world environment. The latter component was, in fact, what gave the creation a spectrum-wide presence, and as a result, initiated a full-blown tech revolution. Of course, this revolution eventually went on to scale up the human experience through some outright unique avenues, but even after achieving a feat so notable, technology will somehow continue to bring forth the right goods. The same has turned more and more evident in recent times, and assuming one new discovery ends up with the desired impact, it will only put that trend on a higher pedestal moving forward.

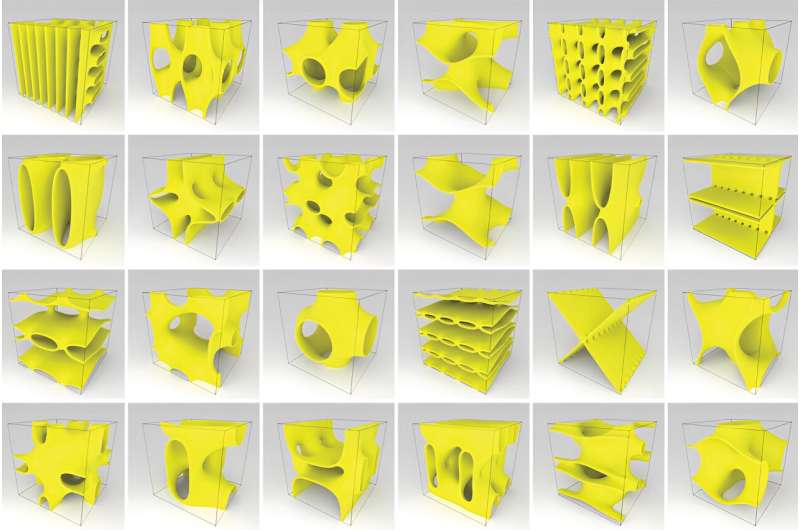

The researching team at Massachusetts Institute of Technology has successfully developed a computational technique which makes it easier for a user to quickly design a metamaterial cell from any of those smaller building blocks, thus simplifying the very prospect of conceiving complicated construction materials. Bearing similarities to a specialized CAD (computer-aided design) system for metamaterials, the new technique allows an engineer to quickly model complex metamaterials and experiment with designs that may have, under previous conditions, taken days or even longer to develop. Not just time, the user-friendly interface understood be employed here, given the fact that all possible building blocks are available, also enables you to explore the entire space of potential metamaterial shapes. Now, before we dig any further into the technology, it’s important to have a clear about what exactly are these cellular metamaterials. You see, they are artificial structures composed of units or cells that can repeat in various patterns to potentially help engineers in creating property combinations and achieving desired performance across different areas. However, despite their huge potential, it remains a challenge to know which cellular structure will lead to the desired properties. Such a roadblock meant one could explore only a small proportion of all the cellular metamaterials. Enter the discovery in question. The researchers basically used their system to recreate structures that spanned across many unique metamaterials’ segments. Once the skeletons were duly designed, each metamaterial structure took only a few seconds to generate. The team also created automated exploration algorithms and gave each a set of rules and then left it loose in their system. That being said, this is not what made the discovery so valuable. Instead, it was the way our new computational technique overcame the limitations created by a need to choose one representation which will be used to describe potential designs. Usually, depending upon what you choose, you will be provided a set of shapes that will be available for exploration, but like anyone can guess, it will simultaneously prevent you from exploring metamaterials based on other elements.

“By choosing a specific subspace ahead of time, you limit your exploration and introduce a bias based on your intuition. While this can be useful, intuition can be incorrect, and some of the other shapes may have also been worth exploring for your particular application,” said Liane Makatura, MIT electrical engineering and computer science graduate student and co-lead author of a paper on this technique.

Fortunately, the researchers discovered the shapes that comprise the overall structure could be easily represented by lower-dimensional shapes. Another thing they noticed was how cellular metamaterials would often have symmetries, so only a small part of the structure needs to be represented. As for the rest, they can be built by rotating and mirroring the initial piece. This paved the way for cellular metamaterials to be represented in a graph structure, which in turn facilitated the creation of metamaterial skeleton. Next up, the user will employ a function over that line to specify the thickness of the beam. Towards the end, the system produced the entire graph-based procedure, showing every operation the user took to reach the final structure, all the vertices, edges, solvers, transformations, and thickening operations. Complementing the same is the option to preview the current structure at any point in the building procedure and directly predict certain properties, empowering users to make timely tweaks.

The credibility of this technique was validated when the researchers put it through a test where it was able to deliver more than 1,000 potential truss-based structures in about an hour.

“Our representation makes all sorts of structures more accessible to people. We were especially pleased with users’ ability to generate TPMS. These complex structures are usually difficult even for experts to generate. Still, one TPMS in our study had the lowest average modeling time out of all six structures, which was surprising and exciting,” said Makatura.

For future, though, the plan is to improve the technique by incorporating more complex skeleton thickening procedures. Beyond that, the team is also exploring the possibility of using their system to create an inverse design where one can specify desired material properties and then use an algorithm to find the optimal metamaterial structure.