Human beings have proven that they can be good at a lot of different things, but our greatest ability is, by far, the one that gets us to improve on a consistent basis. This inclination …

Human beings have proven that they can be good at a lot of different things, but our greatest ability is, by far, the one that gets us to improve on a consistent basis. This inclination towards continuous growth has, in fact, already fetched us some huge milestones, with technology emerging as a major member of the stated group. The reason why we hold technology in such a high regard is largely predicated upon its skill-set, which guided us towards a reality that nobody could have ever imagined otherwise. Nevertheless, if look beyond the surface for a second, it will become clear how the whole runner was also very much inspired from the way we applied those skills across a real world environment. The latter component actually did a lot to give the creation a spectrum-wide presence, and as a result, start what was a full-blown tech revolution. Of course, this revolution then went on to scale up the human experience from every conceivable direction, but even after achieving a feat so notable, technology will somehow continue to bring out the right goods. The same become more evident in recent times, and assuming a new development around the climate tech space pans out just the way we envision, it should only help that trend to far bigger heights sooner rather than later.

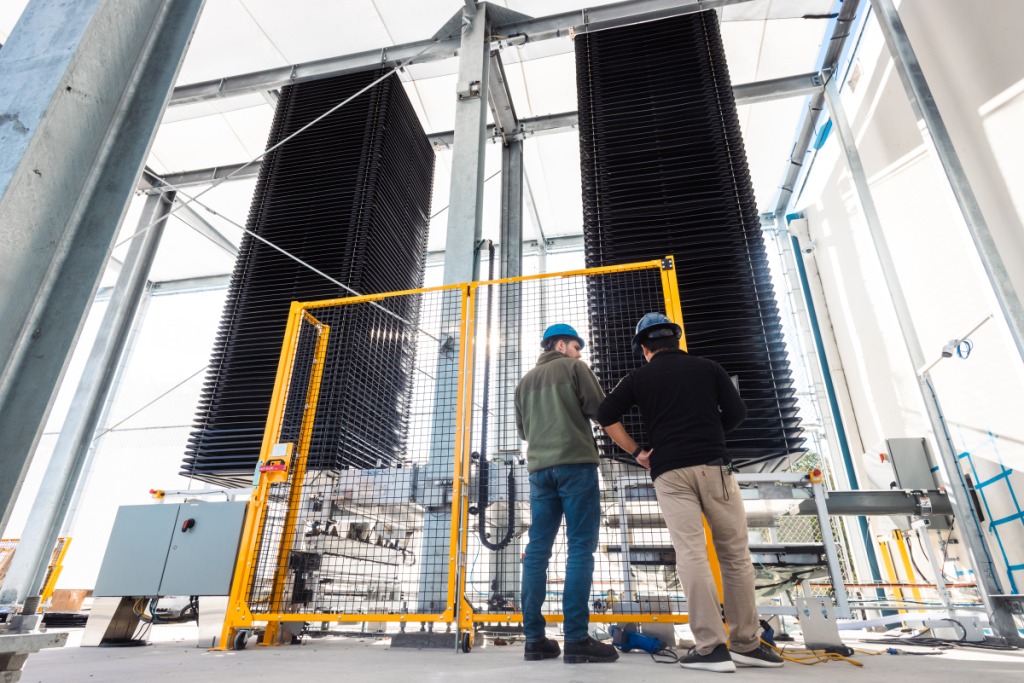

Three climate tech companies, Heirloom, CarbonCure, and Central Concrete Supply Company have successfully completed a demonstration project, which was designed to pull carbon dioxide out of the atmosphere and use it to make concrete for construction projects across California’s Bay Area. Marking the first time anyone has ever put such an approach into action, the project started with Heirloom using calcium oxide from limestone, an agent that acts like a sponge to draw carbon dioxide out of the air. To give you exact numbers, the company was able to pull more than 30 kg CO2. This figure, notably enough, sizes up with tailpipe emissions of driving about 75 miles in a car.

“Limestone has this natural ability to pull carbon out of the atmosphere. The problem is it’s just slow. So what we do here is just give it more superpowers to make it pull carbon much, much, much faster than it otherwise would,” said Shashank Samala, CEO of Heirloom.

Anyway, once the first bit was done, CarbonCure came in with its own technology and injected that captured CO2 into used concrete’s wastewater, and it did so to make it suitable for a reuse. You see, we dump the stated wastewater mainly because it’s considered too reactive to use again. CarbonCure solved that problem through CO2. The move also allowed it to leverage the leftover cement in wastewater. By using that ingredient, the company realized a sustainable creation of more concrete. But how did it manage such a feat? Well, the wastewater cement got the manufacturing process to use a lot less cement than otherwise, something which instantly reduced the emissions that we associate with it. The project in question isn’t CarbonCure’s first ever attempt at using CO2 leftover from industrial processes to make concrete. The company has even supplied this sustainable material for the construction of Amazon’s second headquarters that are located in Arlington, Virginia region.

At last, Central Concrete Supply Company rounded things off when it used the treated wastewater to actually create concrete in its manufacturing facility.

Now, although the partners were able to reach their goal, they are now planning to replicate the whole project on a much bigger scale to prove its utility for a wider application.