Human beings do know an awful lot, but at the same time, we are still yet to learn anything more significant than what we know about getting better under all circumstances. This commitment towards growth, …

Human beings do know an awful lot, but at the same time, we are still yet to learn anything more significant than what we know about getting better under all circumstances. This commitment towards growth, no matter the situation, has brought the world some huge milestones, with technology emerging as quite a major member of the group. The reason why we hold technology in such a high regard is, by and large, predicated upon its skill-set, which guided us towards a reality that nobody could have ever imagined otherwise. Nevertheless, if we look beyond the surface for one hot second, it will become abundantly clear how the whole runner was also very much inspired from the way we applied those skills across a real world environment. The latter component, in fact, did a lot to give the creation a spectrum-wide presence, and as a result, initiate a full-blown tech revolution. Of course, the next thing this revolution did was to scale up the human experience through some outright unique avenues, but even after achieving a feat so notable, technology will somehow continue to produce the right goods. The same has turned more and more evident in recent times, and assuming one new discovery ends up with the desired impact, it will only put that trend on a higher pedestal moving forward.

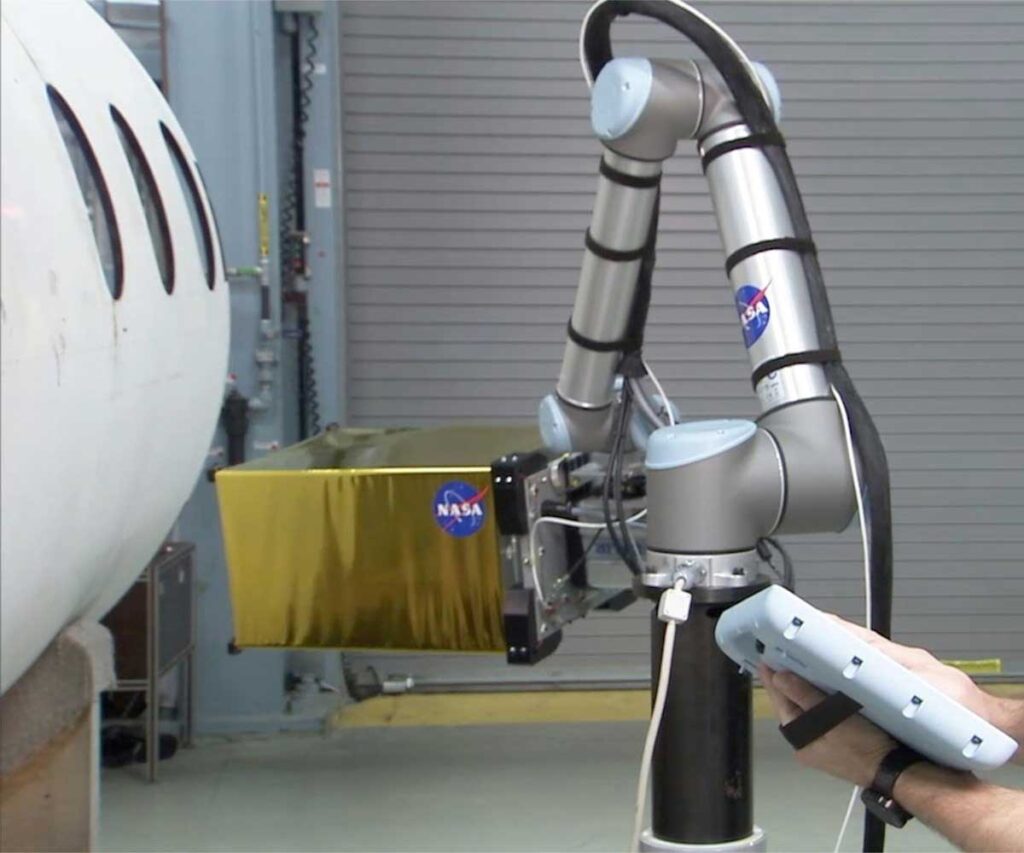

A team at NASA’s Langley Research Center is now officially using multiple collaborative robots (cobots) to automate and streamline the inspection process of aircraft fuselages. Talk about the stated process, it involves large group of testing processes that are used to detect flaws in a manufactured product without destroying it. For the team at Langley, the focus is on performing infrared detection where it effectively heats up the fuselage before bringing an infrared light to detect flaws in the heated material. But what’s the role of cobots here? You see, with this technology, the team can change their method to line scan tomography, meaning they can move the heating element and an infrared camera in a consistent line to ensure a more streamlined operation.

“In conventional tomography, you heat a large area and then inspect one section at a time,” said Elliott Cramer, head of the branch. “Currently, most of these inspections are done on a point-by-point basis. You’ll inspect a small area, then move over the surface either manually or with some kind of scanning system.

According to certain reports, NASA actually forayed in and around this technology using single cobot alongside one sensor. However, with two cobots, it should get one to hold a heating element and move it in a consistent line along the fuselage, whereas the other one holds a FLIR infrared camera. Such a mechanism mobilizes the fuselage immediately behind the heating element. Next up, the heat captured from doing so is then used to form a scan, a scan which the team can analyze to spot any issues in the material. Another thing the new technology does is that it significantly increases the task’s working area. Given how two cobots are fixed onto a Festo linear actuator, it becomes possible for them to to move along a much longer length of the fuselage, while simultaneously ensuring that their speed remains similar throughout the proceedings. As for what makes the technique in question a more attractive prospect than any manual inspection you can ever conduct, the answer talks to better repeatability, speed, accuracy, autonomy, and coverage. To give you a bit more detail, when performing a manual scan, the sensor can never be positioned in exactly the same place every time, therefore mandating the user to initiate a time consuming process of repositioning the sensor by hand.

“The main advantage is repeatability if you need to go back to an inspection location again, either to reinspect or with another technique,” said Cramer. “Having the robots do it allows you to go back very accurately.”

Not just time-consuming, the manual technique won’t even guarantee that you would achieve full coverage of the aircraft fuselage due to the inaccuracies caused by manually placing the sensor.

Created by Universal Robots, the cobots are supported by simulation software from a company called RoboDK. The stated software has a big role because, after locating the fuselage in space and relative to the robots, the team will create a path in RoboDK. This path is what will then guide the cobots to execute their inspection task and build an infrared scan of the fuselage.

“One of the other things that we’re working toward is the ability to automatically map the data that we collect to an image of the fuselage,” Cramer says, underscoring the importance of having a digital record. “That will ensure the long-term durability of those vehicles as they fly. The ultimate goal is to increase the safety of air travel.”