There might be a lot that human beings can do well, and yet there is nothing we do better than growing on a consistent basis. This progressive tendency on our part has already enabled us …

There might be a lot that human beings can do well, and yet there is nothing we do better than growing on a consistent basis. This progressive tendency on our part has already enabled us to hit upon some huge milestones, with technology appearing a rather unique member of the stated group. The reason why technology’s credentials are so anomalous is largely based on its skill-set, which was unprecedented enough to realize all the possibilities for us that nobody could have ever imagined otherwise. Nevertheless, if we look a little bit closer, it should become clear how the whole runner was also very much inspired by the way we applied those skills across a real world setting. The latter component was, in fact, what gave the creation a spectrum-wide presence and made it the ultimate centrepiece of every horizon. Having such an ingenious tool run the show, unsurprisingly enough, scaled up the human experience in every conceivable sense, but even after reaching so far, the prodigious concept of technology will somehow keep on bringing all the right goods to the table. This has only turned more evident over the recent past, and truth be told, a newly-launched system can do a lot to make that trend bigger and better moving forward.

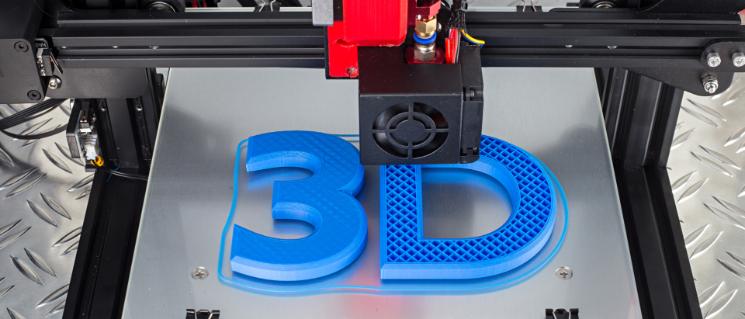

Formlabs, a 3D printing giant based in Somerville, Massachusetts, has officially launched a new automation ecosystem, which is designed to enable new levels of 3D printing productivity that takes the technology closer to becoming mainstream. Talk about what all is included in the stated ecosystem; it starts off from Form Auto that comes with automatic part removal capabilities. Next up, we have an improved Fleet Control setup which now boasts a dedicated dashboard and PreForm so to introduce queue management and optimize the overall workflows. Lastly, the new ecosystem has a High Volume Resin System that increases the resin capacity by a whopping 500%. On a more actionable note, this takes the 1-liter cartridge the printers use today to a five-liter tank that is understood to be compatible with the Form 3+, Form 3B+. Form 3L, and Form 3BL. Beyond the quantity element, though, the new resin system takes up an added responsibility to streamline workflows with consistent resin dispensing, which is done through a specialized resin pump, while also reducing downtime and user intervention to change cartridges and packaging waste.

“The Formlabs Automation Ecosystem is a seamless solution for ramping up production with 3D printer fleets, staying true to the ease of use of all Formlabs products, so anyone can make anything. These solutions will enable companies such as dental labs, service bureaus and internal job shops to ramp up production without increasing labor requirements or expensive capital investment, making 3D printing for production more cost-effective,” said David Lakatos, Chief Product Officer at Formlabs.

Going by the company’s word, these innovations deliver a three-time increase in productivity, but at the same time, reduce 80% of the costs expended on labor. Furthermore, they have shown to bring down cost per part by 30%, while also triggering a sizeable 90% reduction in the total packaging waste.

All in all, these figures, assuming they materialize on the big scale too, should be able to enhance 3D printing’s position across large-scale adaptation in consumer products, prototyping, product design, and dental applications.

“Formlabs users have recently achieved a major milestone, with more than 100 million parts printed on our 3D printers, and by adding this ecosystem, Formlabs is increasing the capacity so users can deliver further 3D-printing innovation,” said Lakatos.