A new chapter for industrial additive manufacturing as Cubic Ink unveils advanced resins, breakthrough collaborations, and large-scale resin production. Berlin, Germany, 2 December 2025 — Cubic Ink is expanding its influence in the global additive …

A new chapter for industrial additive manufacturing as Cubic Ink unveils advanced resins, breakthrough collaborations, and large-scale resin production.

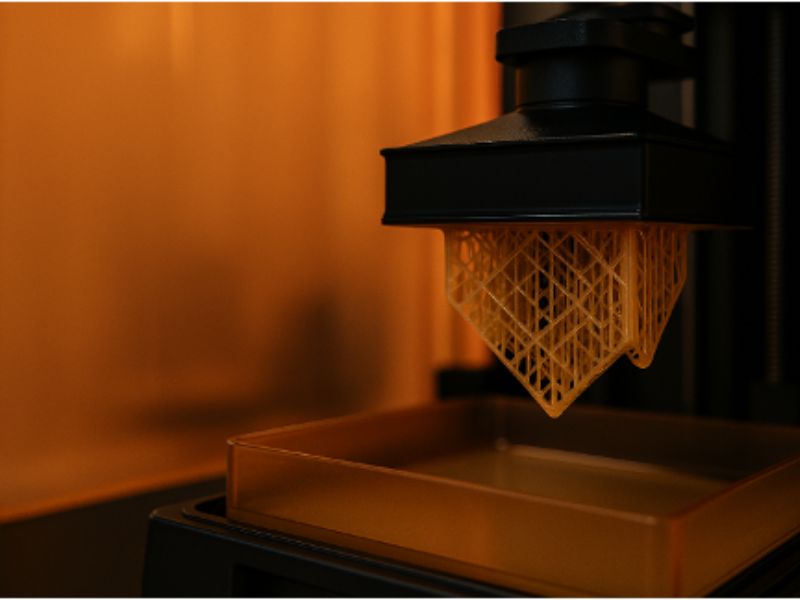

Berlin, Germany, 2 December 2025 — Cubic Ink is expanding its influence in the global additive manufacturing sector with the launch of new resin-based 3D printing materials, a strategic technology partnership with SK Industriemodell, and the successful scale-up of UV-curing resin production in the United States. The company’s latest developments mark a significant step toward more efficient, high-performance, and commercially viable industrial 3D printing.

Dr. Max Röttger, head of Cubic Ink, emphasized the company’s mission to empower innovation. “We give shape to ideas by expanding our portfolio with advanced materials and application-specific solutions,” he said. “Our specialized photopolymers already support customers worldwide with exceptional performance tailored to industrial needs. As a technology leader, our goal is to unlock the next level of additive manufacturing.”

Cubic Ink continues to strengthen its position as a manufacturer-independent material supplier for DLP, LCD, and SLA technologies. Its portfolio includes resins for casting, toolmaking, functional prototyping, high-temperature parts, and material jetting. The newly introduced materials offer improved performance for industries such as audiology, dental care, medical orthopedics, and injection molding.

Among the standout innovations is the Cubic Ink Mold 3100 VP, designed to create mechanically easy-to-break silicone molds on common DLP, LCD, and mSLA printers. This material is ideal for audiology applications that require precise, customized molds.

Cubic Ink Dental 3000 VP is another key development. This customizable, user-friendly resin produces highly detailed impression molds for thermoforming dental aligners. Its accuracy and surface quality make it especially valuable for dental professionals.

The company has also introduced Cubic Ink High Performance 4-4800 VP EU, a robust material offering strong impact resistance and heat tolerance. Having passed cytotoxicity testing, it is now suited for medical and orthopedic applications needing durable, safe, and high-performing parts.

A major highlight of Cubic Ink’s latest advancements is its partnership with SK Industriemodell, a leader in turnkey 3D-printed tooling solutions. Together, the companies are enabling fast, flexible, and cost-effective production of prototypes and small-batch parts using original series materials.

This collaboration uses innovative “Print & Inject” technology, allowing Cubic Ink molding materials to create injection molds directly through 3D printing. These reusable or water-soluble molds can process advanced engineering plastics such as PA66 GF, PPS, and PEEK — materials typically used in demanding industrial environments.

Adding to its momentum, Cubic Ink has successfully scaled up U.S. production of UV-curing resins for serial manufacturing. Working with ALTANA’s ACTEGA division, the company began producing large-volume resin batches for medical technology applications in early 2025. This expansion supports faster delivery, improved supply stability, and wider adoption of Cubic Ink materials across the U.S. and, eventually, Europe.

With these innovations, Cubic Ink continues to demonstrate its commitment to shaping the future of industrial additive manufacturing — blending material science, engineering, and strategic partnerships to enable new levels of performance and scalability.